14661 viewsThe drill collar is used to increase the self weight of the drill string to provide more weight on bit and speed up the footage. Because of its strong rigidity and good stability, it also plays the role of centralizing the bit to maintain the well trajectory. Based on API 7-1 specifications, RockySea petro owns rich manufacturing experience in round drilling collar and common drilling collar.

DESCRIPTION

Round drill collars are slick thick-walled round pipes with integral structure, so also called integral drill collars or slick drill collars. The thickness is generally 38-53mm, which is more than four times that of conventional drill pipes. They have greater strength and rigidity

Since the weight on bit is formed by the weight of the drill string, the lower part of the drill string is subject to compressive stress. When drilling, the WOB value is generally greater than the critical value of the pressure bar stability of the drill string, so the drill string at the lower pressure part will bend under its own weight. When the bent drill string rotates, it will cause alternating stress, which will lead to fatigue failure of the drill string. In order to reduce the degree of fatigue failure, the bending stress should be reduced. This requires shortening the length of the compression section and increasing its rigidity. Therefore, drill collars are used instead of drill rods at the lower end of the drill string.

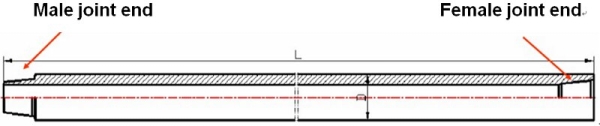

Basic Structure

For drilling collars, joints are directly turned on both ends of the pipe body without additional joints

TECHNICAL DATA

Parameters

|

OD range |

Yield strength |

Tensile strength |

Elongation |

Hardness |

Charpy impact energy | |

|

mm |

in |

MPa |

MPa |

% |

HB |

J |

|

79.4~171.4 |

3 1/8~ 6 3/4 |

≥788 |

≥1005 |

≥13 |

295~341 |

≥70J |

|

177.8~279.4 |

7~11 |

≥719 |

≥960 |

≥13 |

295~341 |

≥70J |

MORE DETAILS

Functions

1) Apply WOB to the bit

2) Keep the drill pipe in tension and ensure the strength of the drill pipe under compression

3) Reduce the vibration, jump and swing of the drill bit to make it work smoothly

4) Controlling well deviation